16 Applications of Computer Vision in Construction (2024 Guide)

Contents

- Construction Equipment Detection and Tracking

- Asset Management and Maintenance

- Automated Quality Control

- Dangerous Goods Sign Recognition

- Automated Inspection with Al Vision

- Process Optimization and Tracking

- Read Analog Dials with Al Vision

- Measure Distances and Volume

- 3D Scanning of Infrastructures

- Outdoor and Indoor Mapping

- Safety and Security Monitoring

- Automatic Construction Zone Detection

- Material Management with Al Vision

- Intelligent Workforce Management

- Detection of Structural Defects in Buildings

- Construction Vehicle Identification

- The Bottom Line

- Starting with Computer Vision

Computer vision is making a huge impact on the construction industry! By automating tasks, reducing costs, and increasing accuracy, computer vision technology changes the way we develop construction AI project plans. In this article, we will explore some of the most exciting applications of computer vision in construction.

Edge AI and Computer Vision are enabling new applications in the construction industry by providing real-time information and scalable, distributed intelligence at the project site. This allows construction managers to make better decisions, reducing waste and improving efficiency.

About us: ProX PC is the leading infrastructure for developing and operating real-world computer vision applications. Leaders in the construction industry harness the power of AI vision to digitize their operations and gain a competitive edge.

Construction Equipment Detection and Tracking

Additionally, by tracking the presence and movement of equipment, machine learning can recognize cranes, bulldozers, excavators, and loaders. Hence, construction managers can make sure that machines are being used efficiently and reduce waiting times in specific areas (regions of interest).

Different variations of intelligent solutions use object detection algorithms to detect construction vehicles, and prevent machinery from blocking walkways or exits.

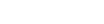

Personal protective equipment (PPE) detection with deep learning

Asset Management and Maintenance

Computer vision can be used to keep track of the condition of construction assets. This can help with asset management, as it allows managers to keep track of which assets need repairs or replacements. It can also help with maintenance, as it can alert workers when an asset is starting to wear down and needs to be repaired or replaced.

By using AI-powered vision intelligence, the lifetime of assets can be improved, waste is reduced, and expensive interruptions and delays can be reduced and shortened. In addition, maintenance is essential to meet safety standards and comply with legal requirements.

Person detection using the object detector YOLOv7

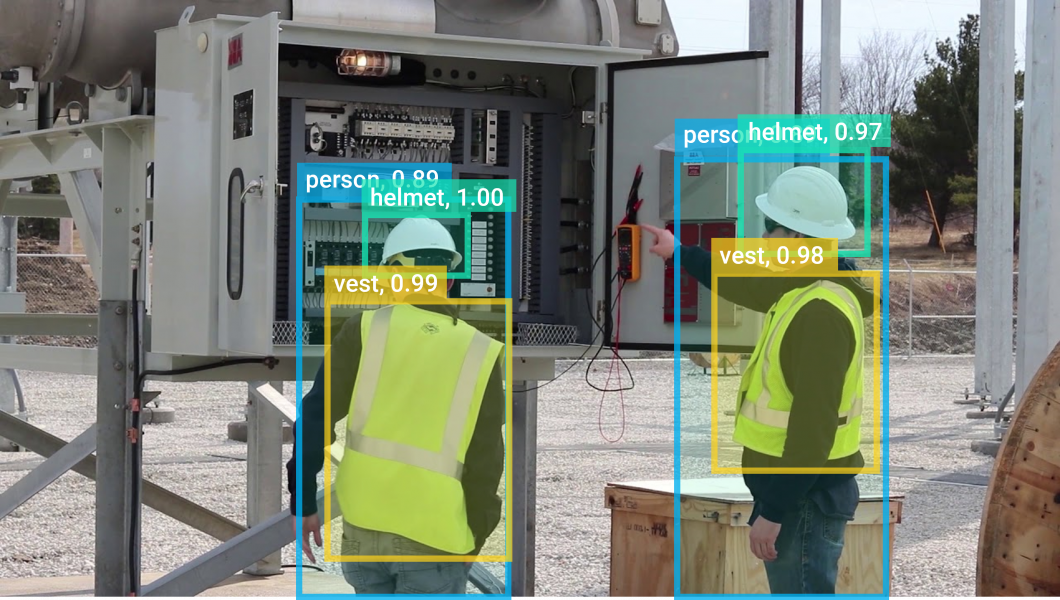

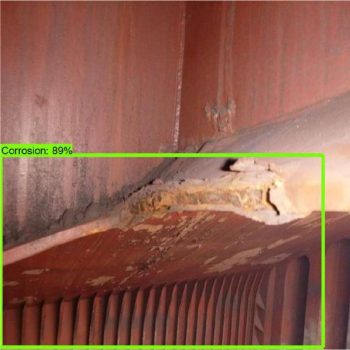

Automated Quality Control

Computer vision can be used for automated quality control for construction materials. By using camera sensors to detect and identify irregularities in the material, computer vision can be used to ensure that the construction process is as accurate as possible. This can help to reduce the number of errors and improve the overall quality of the finished product.

This can help save time and money by catching errors early on in the production process. For example, a construction firm can use AI vision to automatically inspect the quality of the concrete being used in a building project. If there are any defects identified, the company can then take corrective action before it causes further damage.

Examples of automated quality control for construction materials include:

- Using sensors to detect and identify irregularities in the material

- Checking the consistency of the material

- Monitoring the color of the material

- Checking the dimensions of the material

- Detecting and identifying defects in the material

- Classifying the type of material

Quality control with deep learning for defect detection

Dangerous Goods Sign Recognition

Dangerous goods sign recognition using computer vision algorithms is an effective way to identify hazardous materials in a fast and accurate manner. Through the use of deep learning algorithms, computer vision systems can be trained to detect, recognize, and classify signs associated with hazardous materials and substances such as explosives, flammable liquids, radioactive substances, and corrosives.

This construction technology allows for more efficient safety protocols and control of hazardous materials while reducing the potential for human error. Additionally, applying computer vision technologies for sign recognition helps in other safety-related tasks, such as monitoring hazardous areas, real-time risk assessment, and personnel tracking in facilities.

Dangerous goods sign recognition with real-time deep learning

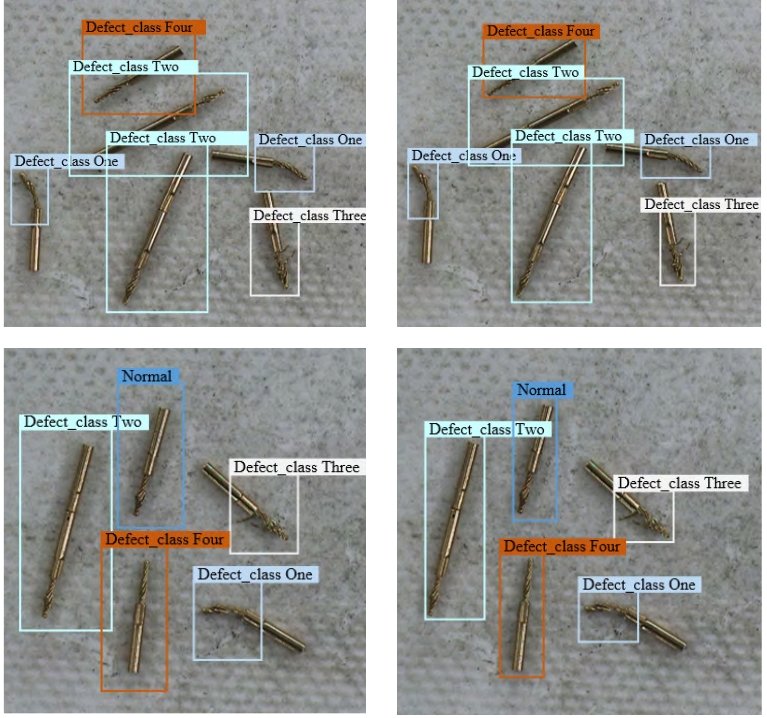

Automated Inspection with AI Vision

Computer vision can be used to automatically inspect personal protective equipment (PPE), inspect construction vehicles and machines, or detect environmental safety hazards at construction sites. This enables enormous time savings for construction companies, as it eliminates the need for manual inspection while ensuring consistent and subjective inspection results.

Using intelligent vision analysis, companies can automatically evaluate the quality of materials and workmanship. This makes it possible to ensure that standards are met and reduces the chances of defects.

Corrosion detection with deep learning

Process Optimization and Tracking

Computer vision technology can be used to track the progress of construction projects. This is immensely helpful for project managers, as it allows them to understand how the project is progressing and identify any potential issues early. This enables project managers to optimize the construction process and make sure that projects are completed on time and within budget.

In construction, human-computer interaction (HCI) is used to help manage processes and monitor a wide range of tasks. Examples include

- Detecting when a worker breaks safety protocols (event detection)

- Ensure that the correct construction materials are used (type classification)

- Inspecting construction sites for safety hazards

- Monitoring the color of construction materials (cable color recognition, etc.)

- Dimension checking of construction materials

- Detecting and identifying defects in construction materials (anomaly detection)

Computer Vision system to analyze the activity of excavators

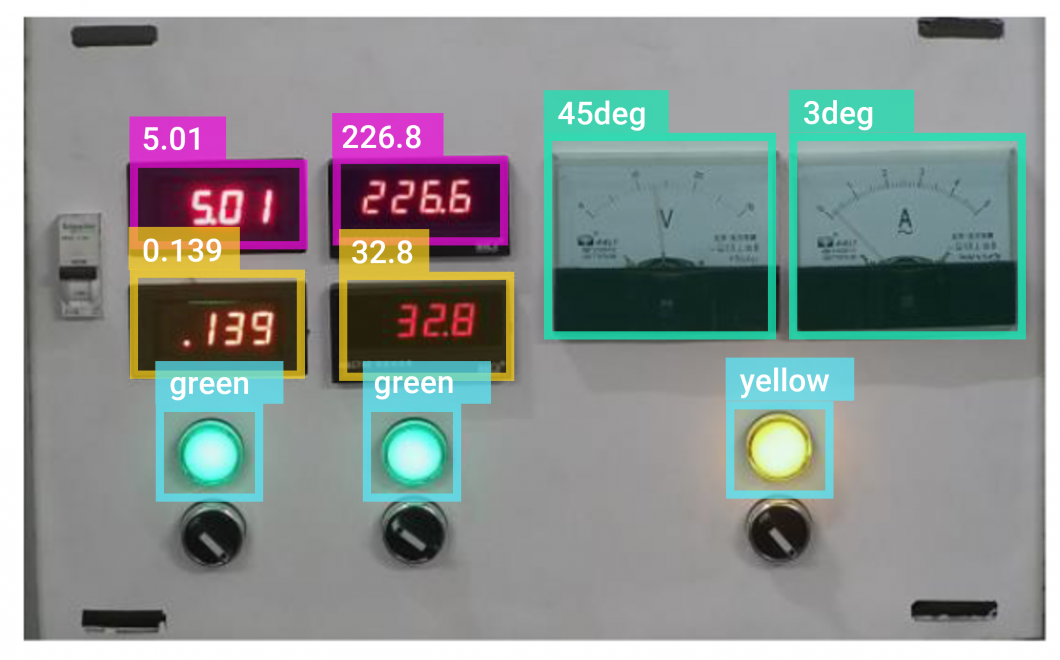

Read Analog Dials with AI Vision

Image recognition applications can be used to read analog dials and displays. The digitization of indicators and reading of displays from machines makes it possible to use this information without having workers physically go to the device and read it.

Such applications can be implemented at an IoT scale to provide real-time information (see AIoT). This enables better and faster decision-making and improves safety because workers no longer have to visit potentially dangerous areas to take readings.

For example, deep learning models can be trained to read:

- Dial indicators

- Pressure gauges

- Level indicators

- Temperature gauges

- Flow meters

Computer vision application to recognize signal lights and mechanical controls – ProX PC

Measure Distances and Volume

Al and machine learning applications can be used to estimate distances, angles, and other dimensions. This can help with tasks such as creating blueprints and mapping out construction sites

In addition, computer vision can be used to measure the volume of construction materials. This is helpful for planning and budgeting purposes, as it allows construction companies to accurately estimate how much material they will need.

One example is the use of cameras or drones (UAV) with computer vision algorithms to measure the volume of earth that has been moved during a construction project. Alternatively, volumes of material loaded onto trucks can be estimated in combination with the counting of the number of trucks at a construction site.

Vision-based technologies provide a more accurate way to measure volume than traditional methods such as surveying or using a measuring wheel.

3D Scanning of Infrastructures

Computer vision can also be used to create as-built models of existing structures. This is especially useful for construction projects that involve renovating or expanding an existing building.

Point cloud algorithms are a way to understand the 3D shape of an object or room, with many use cases in architecture and engineering. They work by taking pictures of an object from many different angles and then combining all of the pictures into one 3D image. Point clouds can be used to create a model of an object, or to analyze the distance between objects.

Outdoor and Indoor Mapping

Computer vision can be used for outdoor and indoor mapping applications. Outdoor mapping is primarily used for navigation tasks, while indoor mapping can be used for a variety of purposes, such as tracking the location of people or objects in buildings or areas.

Al-based mapping applications often use distributed Edge computing systems to apply deep learning for image recognition at scale. There are a variety of computer vision algorithms that can be used for mapping:

1. Feature detection algorithms can be used to identify salient features in an image, such as corners or edges.

2. Tracking algorithms can be used to track the movement of objects in an image. This allows a real-time understanding of a video stream.

3. Stereo reconstruction algorithms can be used to create a three-dimensional model of an environment from two or more images provided by common RGB or dual- lens cameras.

Safety and Security Monitoring

Computer vision helps to increase safety and security in construction by monitoring the surroundings of workers at all times. Modern machine learning analysis automates the detection of anomalous events. This can be used to detect dangerous events such as people close to heavy construction machinery.

Computer vision can also be used to ensure that construction projects meet all the required standards and enforce adherence to policies regarding equipment usage. This can help to save time and money on the safety examination process, as well as ensure that any issues are identified and rectified as soon as possible.

In addition, security cameras can help to deter crime and vandalism on the construction site. Computer vision is widely used in security and surveillance applications, to monitor large sites and detect intruders or unauthorized activity on construction sites.

Human pose estimation of construction workers – ProX PC

Automatic Construction Zone Detection

Computer vision can be used to automatically detect and classify construction zones to help improve safety and security on the construction site. This is done by using cameras to capture images of the construction site and then using machine learning algorithms to identify the different zones in the image.

In addition, construction sites can be separated into virtual areas allowing construction managers to quickly and easily track where work is taking place and localize any potential hazards.

Material Management with Al Vision

Computer vision is used for material management in many ways. A popular application is the automatic recognition and classification of building materials in an image or video stream. This can be used for inventory management, tracking the use of materials, and more.

Another application is for predicting the quantity of materials that will be needed for a project. By understanding the size and shape of objects in an image or video, we can get a better estimate of the amount of material required. This can help avoid ordering too much or too little material, and optimize logistics to save time and money.

Some examples of materials that can be detected, classified, and managed with Al vision include concrete elements, bricks, pipes, wires, cables, nails, screws, or drywall. Depending on object size and environment, the machine learning algorithm needs to be re-trained and deployed as part of a multi-step computer vision pipeline.

Computer vision application using the real-time object detector YOLOv7

Intelligent Workforce Management

Computer vision can help with workforce management by tracking the movement of workers, vehicles, and equipment on a construction site. Computer vision with cameras set up at key points on construction sites can also monitor the quality of the construction process itself. This technology can be applied to assess the delivery and quality of services provided by subcontractors.

The generated insights can be used to create a map of the job site, which can then be used to identify potential hazards. If a potential threat is identified, the connected AloT application can send a warning to the worker who is in danger or provide reports to direct attention toward high-risk situations and improve training and instructions.

In addition, Al technology systems help managers plan and optimize the workflows, and increase operational efficiency. For example, Al vision analysis can identify shortages of workers in areas of the construction site and help optimize shifts or redirect workers to where they are needed. Such applications help to prevent expensive delays or interruptions.

Automated person detection and counting – ProX PC

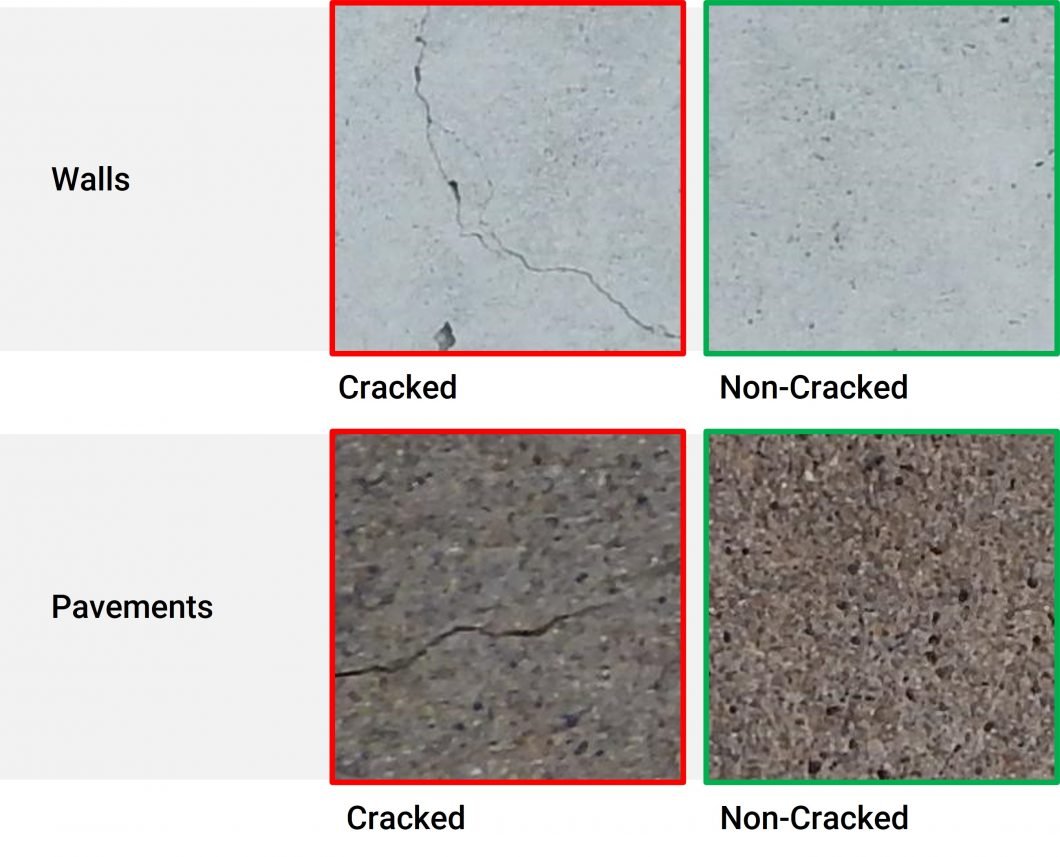

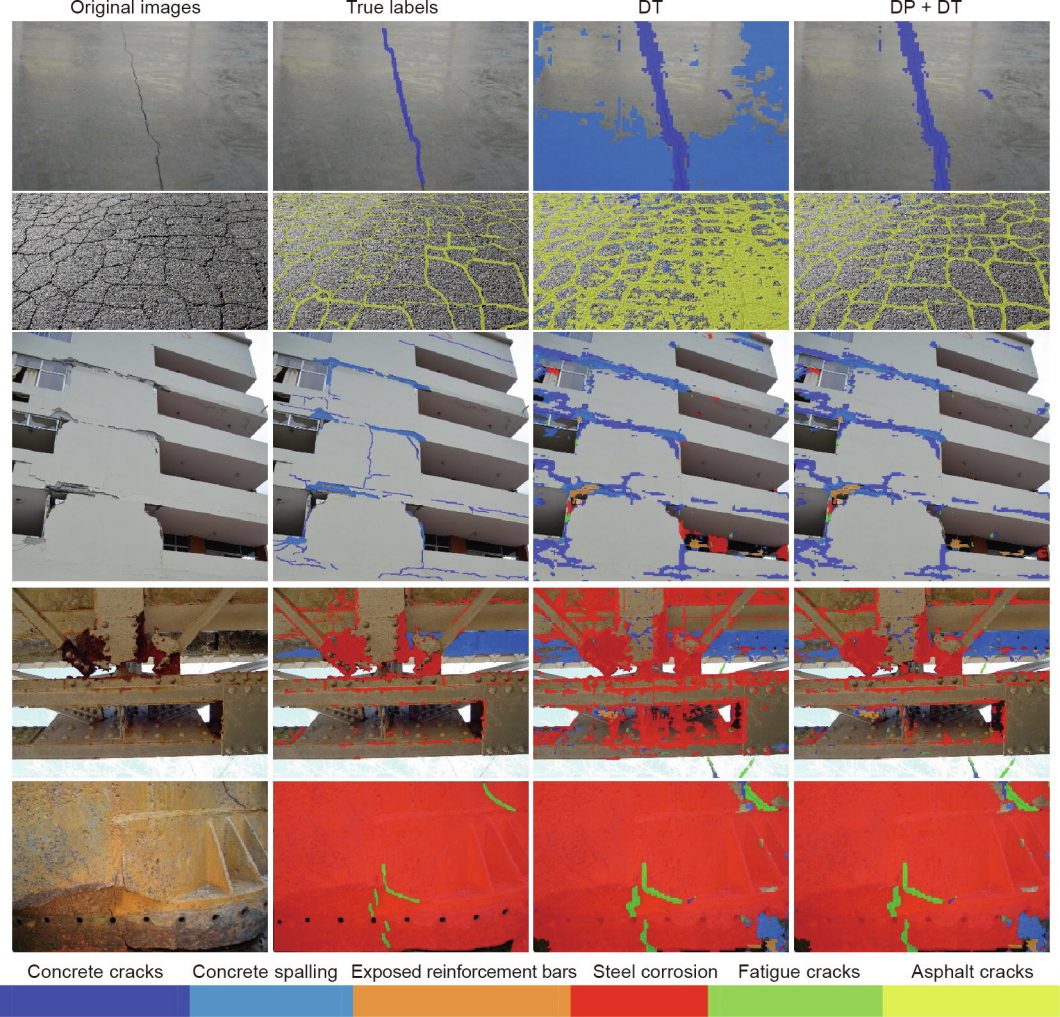

Detection of Structural Defects in Buildings

Deep learning and image processing technologies can also be used to detect structural deficiencies in buildings and bridges. By collecting image data of the structure and analyzing them using computer vision algorithms, flaws can be detected and identified.

Applied Al vision for detecting structural defects

Such infrastructure analysis can help to ensure that the structure is safe and does not pose a danger to the people or property in the area. In some cases, this information is useful for evaluating liability risks, property value, or insurance costs.

Some examples of structural defect detection include:

- Detecting cracks in the structure

- Detecting misaligned or faulty joints in the structure

- Identifying faulty construction materials

- Identifying loose or missing bolts or screws

- Checking for signs of corrosion or water damage

- Detecting movement or displacement in the structure

Applied infrastructure inspection with computer vision

Construction Vehicle Identification

Automated number plate recognition (ANPR) is useful at construction sites to help control traffic. Computer vision applications can analyze real-time video feeds from common CCTV or security cameras to recognize license plate numbers.

The information can help managers track vehicles entering and exiting a construction site. This helps to ensure safety by knowing who is entering or leaving different areas without depending on human operators. Automated number plate recognition can also identify vehicles without proper permits or that are involved in suspicious activities.

Number plate recognition for automated vehicle identification

Such contactless automation of vehicle identification reduces administrative workloads, reduces congestion, and waiting times. These insights can assist in tracking and optimizing schedules, site layouts, and procedures.

The Bottom Line

The applications of computer vision in construction are vast and varied. By using AI vision to detect, classify, and manage materials, workers, and vehicles, construction managers can optimize operations and ensure on-site safety.

As technology continues to develop, more applications of computer vision in construction are becoming technically possible and cost-effective. Distributed computer vision infrastructures are the driving force behind the efficiency optimization of AI applications in construction.

Starting with Computer Vision

ProX PC is the world’s only end-to-end computer vision platform for organizations to build, implement, and scale custom applications. Get in touch and request a product walk-through.

For more info visit www.proxpc.com

Related Products

ProX MicroEdge Orin Nano

- Compact AI accelerator with 6-core Arm® Cortex® CPU and 1024/512-core NVIDIA Ampere GPU with Tensor Cores

- 8GB/4GB of high-speed LPDDR5 memory and NVMe SSD

- Dual GbE ports, Wi-Fi options, and 4G/5G support

- Versatile I/O and robust features

- Ideal for data-intensive tasks and AI innovation

ProX MicroEdge Orin NX

- Compact powerhouse that combines an 8/6-core Arm® Cortex® CPU, a 1024-core NVIDIA Ampere GPU with 32 Tensor Cores, and lightning-fast 128-bit LPDDR5 memory.

- Store and retrieve data seamlessly with an NVMe SSD and Micro SD slot.

- Stay connected with dual GbE ports, Wi-Fi options, and 4G/5G support.

- Versatile I/O options, including USB 3.1 and HDMI, make interfacing a breeze.

- Unlock the future of AI innovation with Jetson Orin NX.

Divyansh Rawat

Divyansh Rawat is the Content Manager at ProX PC, where he combines a filmmaker’s eye with a lifelong passion for technology. Gravitated towards tech from a young age, he now drives the brand's storytelling and is the creative force behind the video content you see across our social media channels.

Share this: